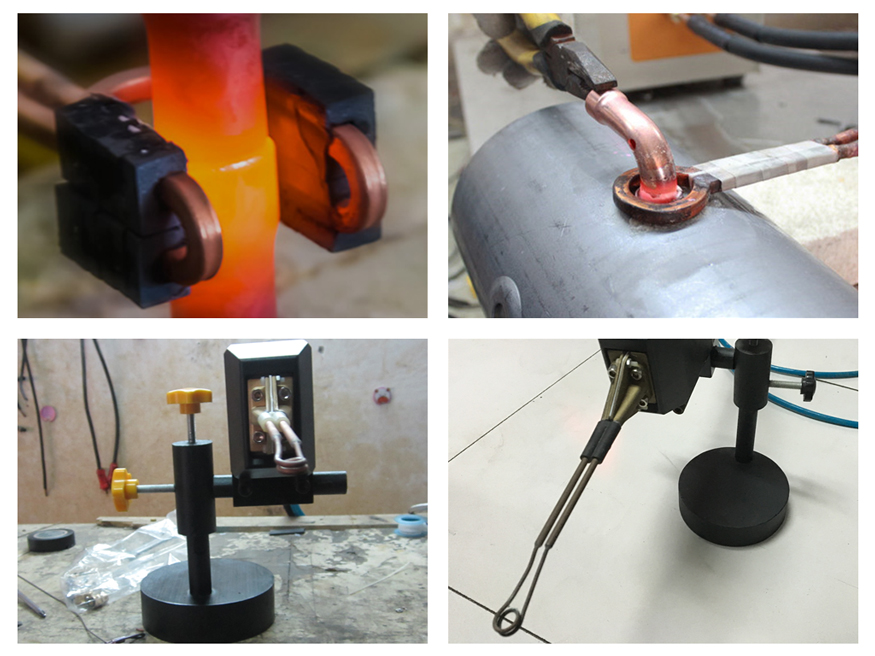

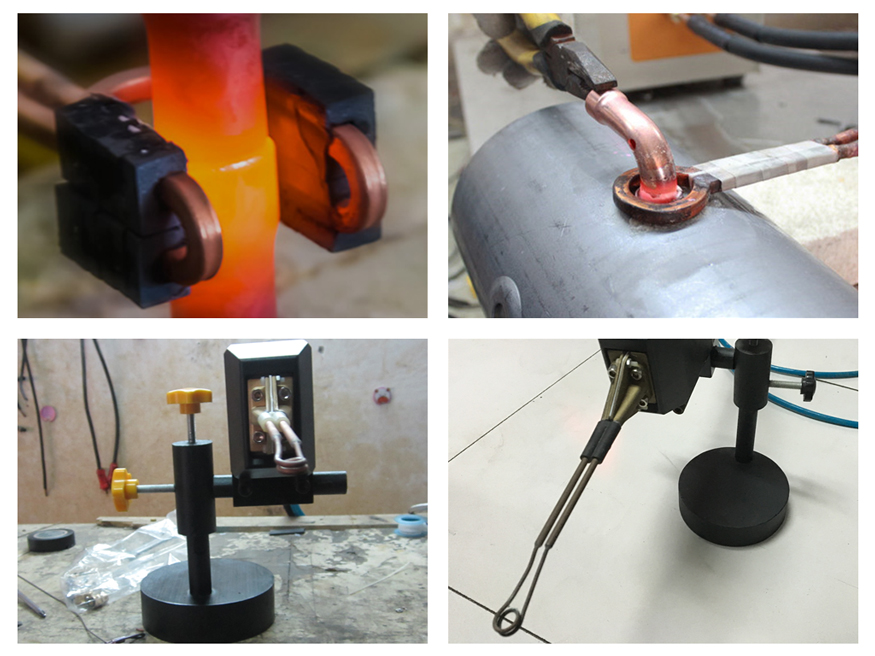

Induction Brazing is a welding method based on high frequency, intermediate frequency, or industrial frequency induction current. Ultrahigh frequency water cooled induction brazing machine is suitable for welding thin wall pipes. Use coaxial cables and split-type induction rings to welded at the scene away from the power supply.

Inductional welding has the advantages of high heating, high productivity, stable operation, continuous work of 24 hours, and high welding quality. It has automatic and manual welding functions, and its operation is simple and practical. Inductional welding is the first choice for products with large output.

High-frequency induction brazing machines from Hitfar include 3.2kw, 4.5kw, 6kw, 8kw, 8kw, 12kw and other customized equipment. It has functions such as simultaneous materials, preheating, welding, pressure preservation, unloading, etc., which can save time and improve production efficiency.

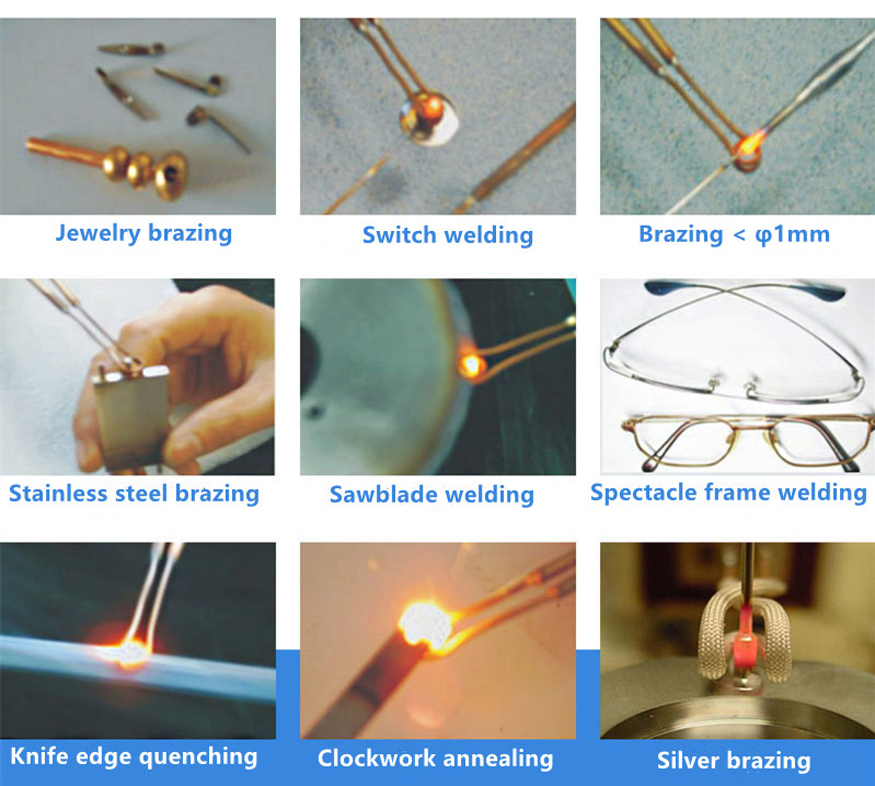

1. High Frequency welding for carbide saw blade tooth with carbide tips.

2. Welding and annealing of eyeglass frames and related accessories.

3. High Frequency brazing for gold, silver, copper and steel jewelry.

4. High Frequency welding for the clock and watch's shells.

5. High Frequency brazing for very fine electronic components.

6. High Frequency silver brazing for small fine metal joints.

7. High Frequency brazing and annealing of wire or strip.

8. High frequency induction heating welding for various tools.

9. Induction hardening for cutter and knife edges.

10. High frequency induction heating tempering for any metal springs or sheets or strips.

MAIN FEATURES

1, Ultra-high frequency up to 1.1MHz, a high-tech product developed with main components imported from Germany.

2, Small in size and light in weigh. Easy to carry by 1 worker.

3, Functions are stable and reliable.

4, Durable time is very long. Some users have been used for very 10year but still work in good conditions.

Ultra-High Frequency Induction Heating Brazing Machine has been widely used in welding high-end glasses frames, gold and silver jewelry and welding of various handicrafts, especially suitable for precision small parts. If you are looking for ultrahigh frequency quenching (brazing) equipment from reliable manufacturer, welcome to contact us for more information!