Guidance before Order:

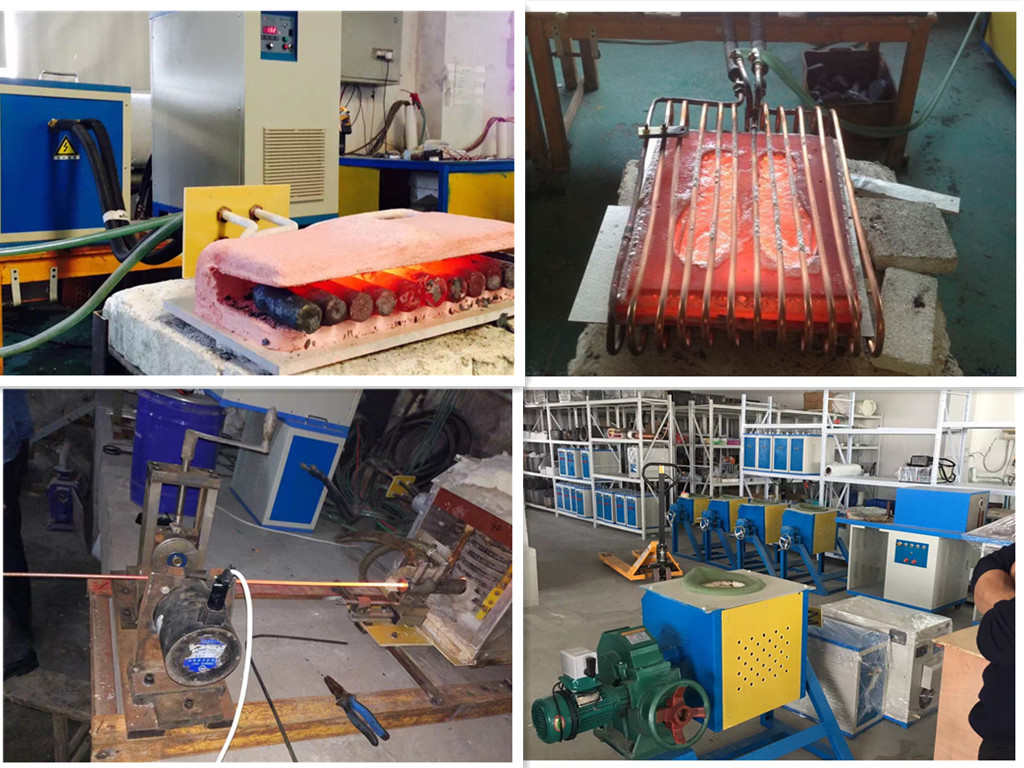

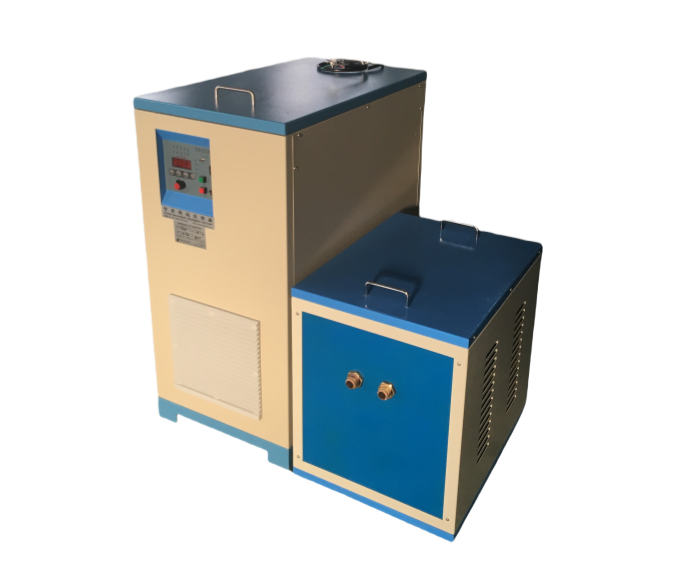

1, We only have medium frequency power supply in stocks. We will match for the proper compensation capacitor and induction coil or heating furnace according to the customer's heating workpiece and heating requirements. Therefore, ordering or consulting customers need to provide the following information:

(1) The material and size of the heating workpiece;

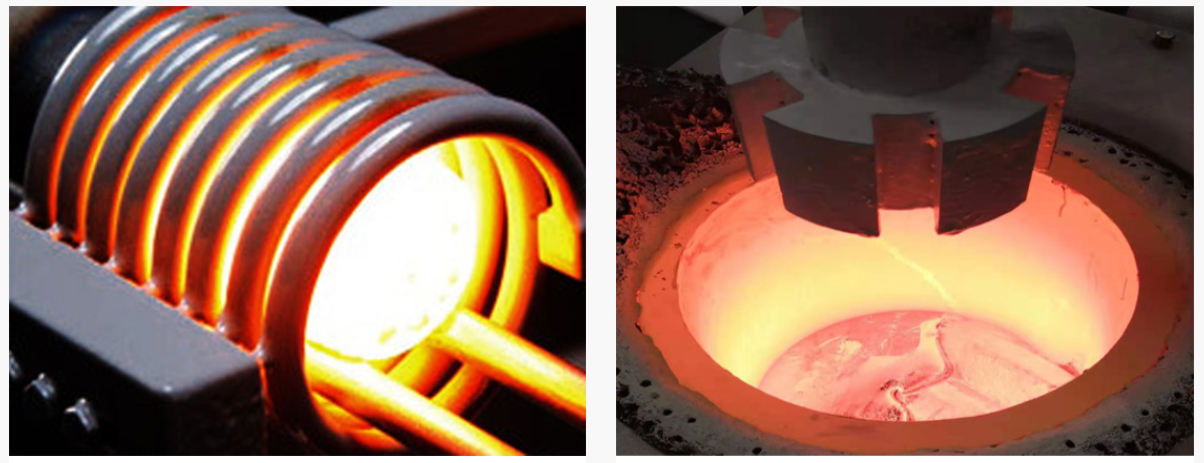

(2) The use of heating and heating temperature, as well as heating time requirements; Is it diathermy or surface heating? If it is surface heating, what is the depth of heating? And so on

(3) There is no limit to the mode and size of the induction coil. Like from the inside or the outside? Closed or open coil? Is there any susceptible metal material within 100MM nearby the induction coil?

(4) Are there any specific requirements for frequency?

(5) Heating atmosphere: in the atmosphere or in the vacuum furnace? Is there a protective gas?

(6) Other details related to the equipment scheme?