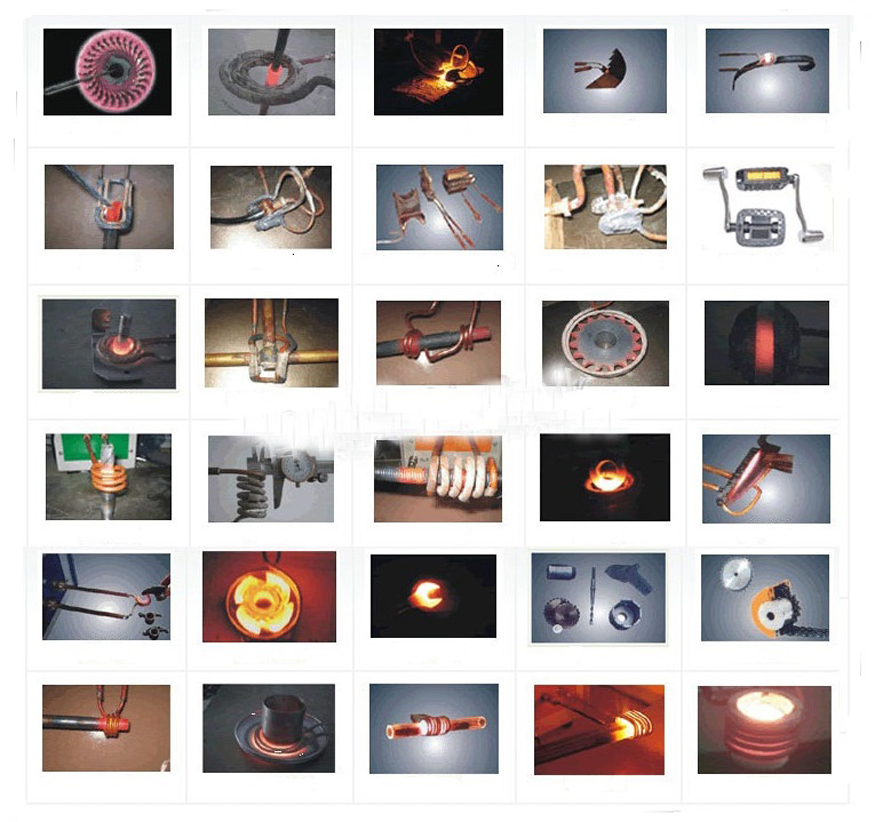

High frequency induction heaters use electromagnetic induction to heat metals and other conductive materials quickly and efficiently. This non-contact heating method ensures precise and uniform temperature control, making it suitable for metal hardening, brazing, forging, and heat treatment. By generating heat directly within the material, induction heating minimizes energy consumption, reduces wear and tear on equipment, and provides faster processing times compared to traditional heating methods.

Our range of high frequency induction heating machine offers high performance, reliability, and energy efficiency, designed for both industrial and laboratory use, providing a cost-effective solution for applications requiring rapid and controlled heating.

(1) High frequency induction heating machine 5KW-100KW from Hitfar adopts the world well-known Siemens MOSFET/IGBT mould as power source to devices and unique inverter technology,100% duty cycle design, 24-hour operation at maximum power, high reliability assurance.

(2) self-controlled adjustable heating time, heating power, holding time, holding power and cooling time; greatly mprove the quality and repeatability of heating heating products, to simplify the operation of technical workers.

(3) light weight, small size, simple installation [a few minutes to complete].

(4) simple, few minutes to learn.

(5) Special Security, the output voltage is below 36V, remove the high voltage electric shock.

(6) the heating efficiency up to 95%, energy consumption is only 20% -30% of the old-fashioned tube, almost no lectricity in standby mode, and 24 hours of continuous work.

(7) the sensor can be freely removable quick replacement, ultra-fast heating significantly reduced the oxidation of the workpiece deformation.

(8) substituted oxygen, acetylene, coal and other dangerous items heated latest environmentally friendly products, no open flame to produce more safe and secure.

(9) the induction annealing machine has over-current, over voltage, over temperature, water shortages, lack of equal perfect automatic protection function, and is equipped with self-diagnostic alarm system.

(10) the apparatus includes a constant current and constant power control function, greatly optimize the process of heating the metal to achieve efficient, rapid heating, the superiority of the product can be fully realized.