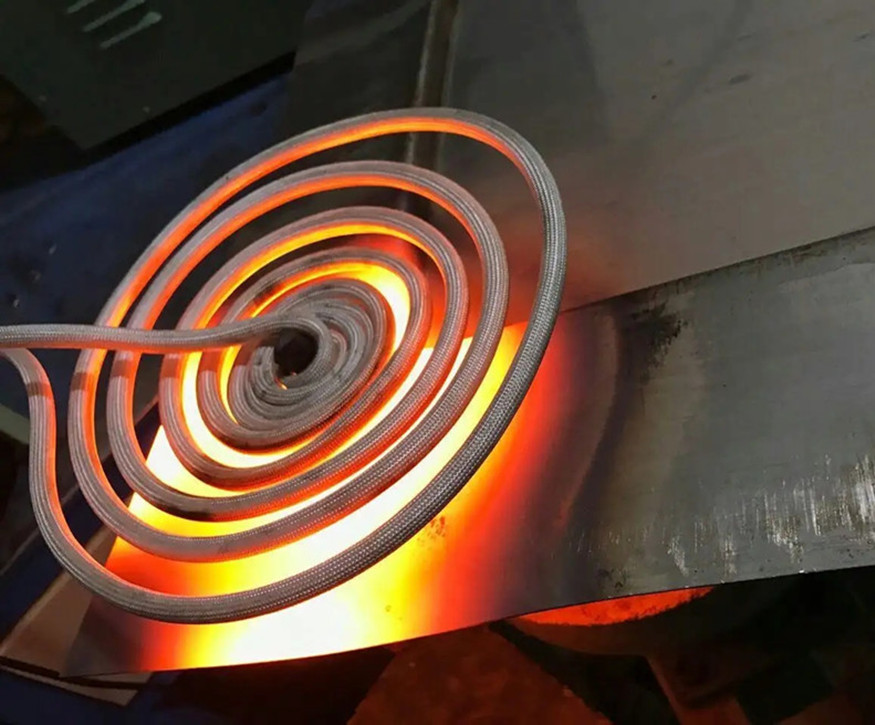

(1) 80KW/30-80Khz High Frequency Induction Heating Machine from Hitfar adopt frequency automatic tracking and multi-channel closed-loop control.

(2) High Frequency Induction Heater is much more safer and energy-saving than other types of heating like substitute oxyacetylene flame, coke furnace, salt bath furnace, gas furnace, oil furnace and other heating methods.

(3) The remote control can be reached by connect wire to PLC.

(4) The heating temperature can be auto-controlled by connecting with an extra infrared temperature controller, which would improve the heating quality of products and decrease the worker to operate.

(5) High frequency induction heating machine has less heat dissipation, little smoke and dust, so the workshop temperature is as normal not to low or too high, which can improve the environment and working conditions of the workshop.