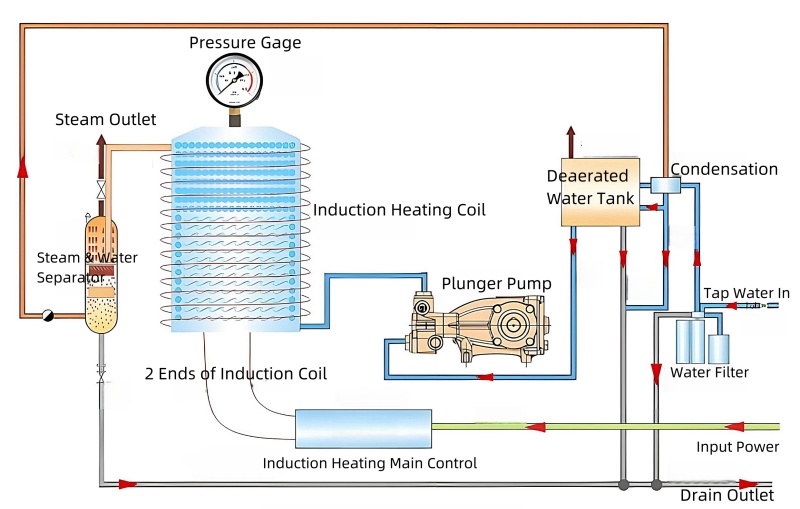

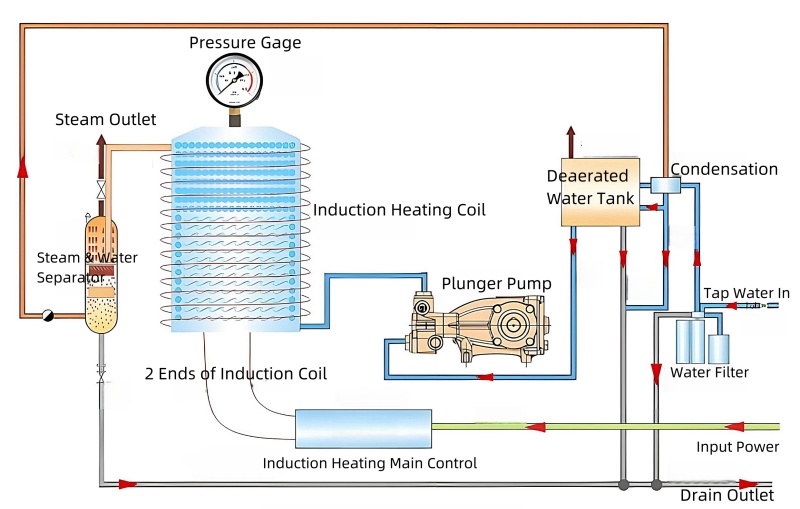

The Working Principle of Electromagnetic Frequency Conversion Energy Storage Induction Heating Steam Generator

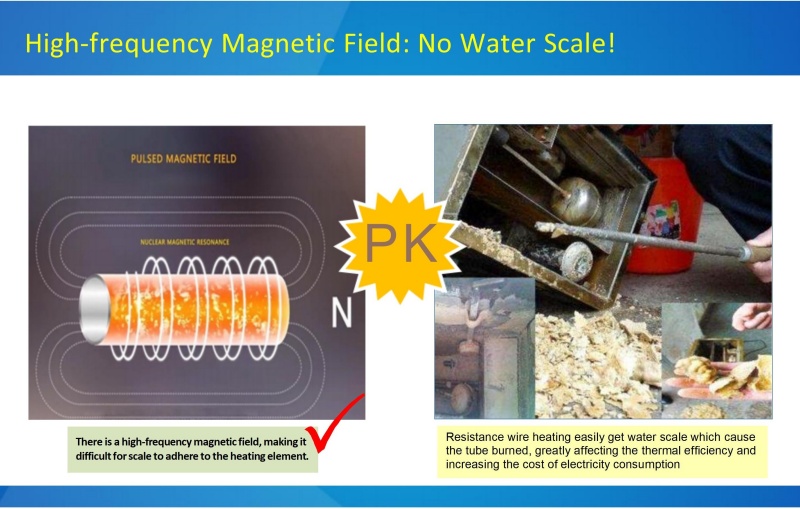

Electromagnetic induction heating steam generator, also known as electromagnetic steam boiler, is a power device that uses the principle of electromagnetic induction eddy current heating to convert electrical energy into thermal energy, and then convert thermal energy into steam. Compared to traditional resistance heating steam generators, electromagnetic steam generators are more economical, capable, safer, and longer lifespan.The structure of the electromagnetic steam generator mainly consists of an electromagnetic induction heater, a pressure vessel, and an induction heating coil, as well as water level display and pressure. In short, induction water boilers are an efficient and environmentally friendly heater that utilizes the principle of electromagnetic induction to convert electrical energy into thermal energy and achieve heating by heating water.

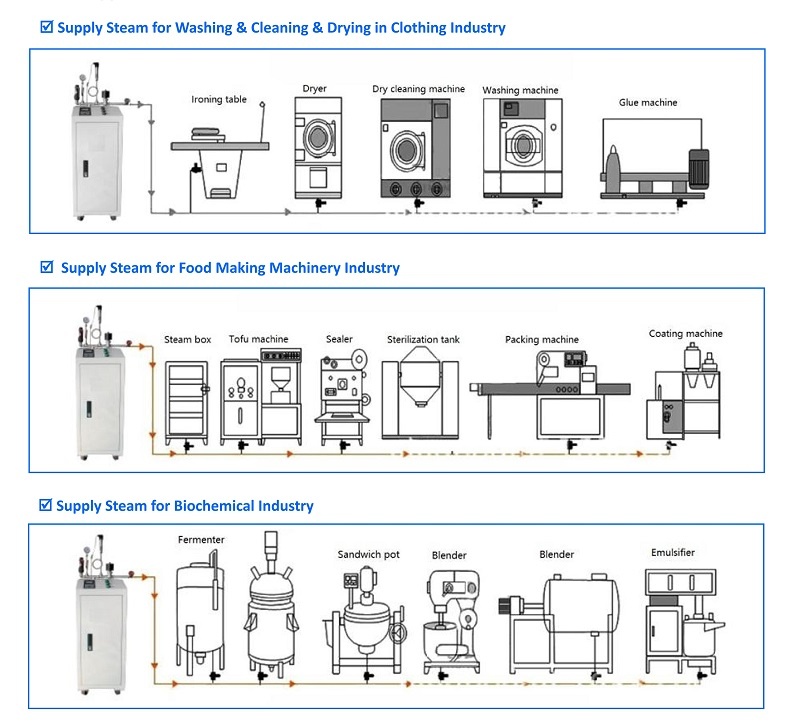

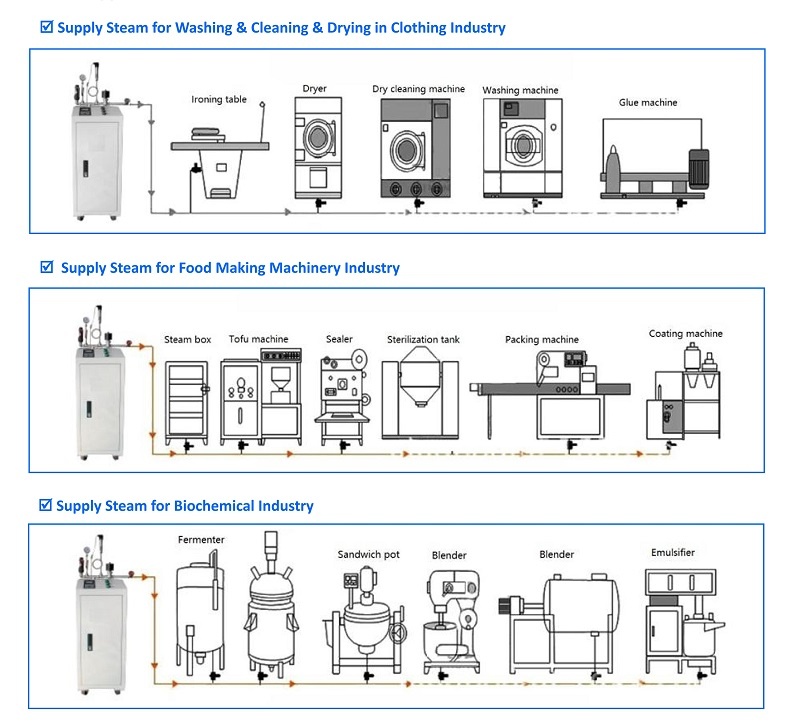

Applications for Electromagnetic Frequency Conversion Energy Storage Induction Heating Steam Generator:

The application scope of electromagnetic steam generator boiler covers multiple industries, primarily used to provide high-temperature and high-pressure steam for functions such as heating, disinfection, and sterilization

Used for food processing, cooking, and sterilization, such as baking bread, steaming meat, disinfecting tableware, and also applicable to brewing processes (e.g., sanctification stages in the production of wine and beer)

2. Medical applications include sterilizing surgical instruments and cleaning dental equipment, achieving efficient sterilization through high-temperature steam

3. Used for heating in chemical reaction processes, such as reactor body heating in the production of synthetic rubber and synthetic fibers

4. Used for heating and drying in processes such as fabric dyeing and towel drying

5. Paper making: Used in production processes such as waste paper inking and paper drying

6. Steel: Heating for auxiliary steel making processes such as temperature maintenance and metal plate forming

7. Applied to heating in thermal power generation boilers and heating systems in thermal power pipelines

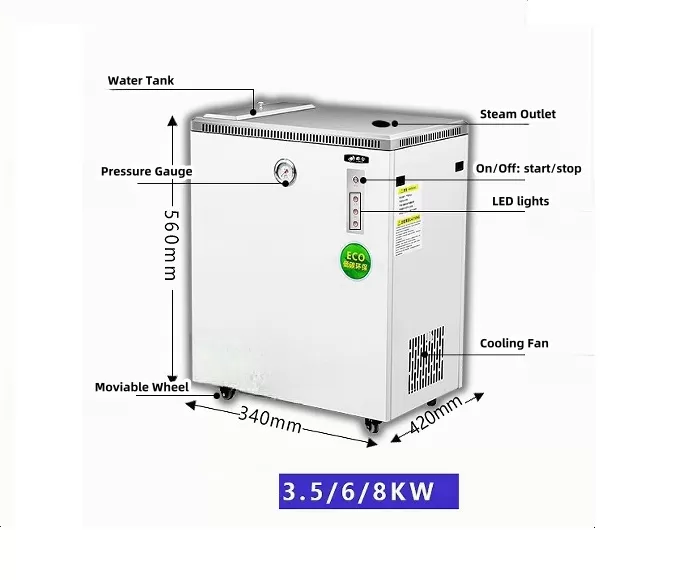

Technical Parameter:

| Rated Power. | SteamTemp. | Heating Current | Steam Pressure | Steam Volume | Heat Exchange Rate | InputVoltage | Steam Outlet Pipe | Safety Value Pipe | Water Inlet Pipe | Sewage Pipe | Dimension(L*W*H) |

| KW | ℃ | A | Mpa | Kg/h | % | V/Hz | / | / | / | / | mm |

| 10kw | 165 | 15 | 0.7 | 14 | 97 | Special Order: 480V, 440V, 415V, 220V3P, 50/60HZ | DN15 | DN15 | DN15 | DN25 | 680*950*1200 |

| 20kw | 165 | 30 | 0.7 | 28 | 97 | DN15 | DN15 | DN15 | DN25 | 680*950*1200 |

| 30kw | 165 | 45 | 0.7 | 40 | 97 | DN20 | DN15 | DN15 | DN25 | 750*950*1380 |

| 40kw | 165 | 60 | 0.7 | 55 | 97 | DN20 | DN15 | DN15 | DN25 | 750*950*1380 |

| 50kw | 165 | 75 | 0.7 | 70 | 97 | DN25 | DN20 | DN25 | DN40 | 800*1100*1780 |

| 60kw | 165 | 90 | 0.7 | 85 | 97 | DN25 | DN20 | DN25 | DN40 | 800*1100*1780 |

| 80kw | 165 | 120 | 0.7 | 110 | 97 | DN25 | DN20 | DN25 | DN40 | 800*1100*1780 |

| 100kw | 165 | 150 | 0.7 | 140 | 97 | DN25 | DN25 | DN25 | DN40 | 950* 1150*2150 |

| 120kw | 165 | 180 | 0.7 | 165 | 97 | DN25 | DN25 | DN25 | DN40 | 950* 1150*2150 |

| 160kw | 165 | 240 | 0.7 | 220 | 97 | DN25 | DN25 | DN25 | DN40 | 950* 1150*2150 |

| 240kw | 165 | 360 | 0.7 | 330 | 97 | DN25 | DN25 | DN25 | DN40 | 1500*1150*2300 |

| 320kw | 165 | 480 | 0.7 | 450 | 97 | DN25 | DN25 | DN25 | DN40 | 1500*1150*2300 |

| 360kw | 165 | 540 | 0.7 | 500 | 97 | DN25 | DN25 | DN25 | DN40 | 1500*1150*2300 |

| 480kw | 165 | 720 | 0.7 | 670 | 97 | DN25 | DN25 | DN25 | DN40 | 2050* 1210*2300 |

| 640kw | 165 | 960 | 0.7 | 900 | 97 | DN25 | DN25 | DN25 | DN40 | 2600*1210*2300 |

| 720kw | 165 | 1080 | 0.7 | 1000 | 97 | DN25 | DN25 | DN25 | DN40 | 2600*1210*2300 |

Why choose Electromagnetic Frequency Conversion Energy Storage Steam Generator?

Please check the table for comparison.

| Steam Generator Type | Gas-fired Type | Electrical Type | Coal-fired Type | Induction Heating Type |

| Energy Used | Gas by Fire | Resistance Wire by Electricity | Coal by Fire | Induction Heating by Electricity |

| Heat Exchange Rate | 85% | 88% | 75% | 98% |

| Need Someone on Duty | Yes | No | Yes | No |

| Temperature Control Accuracy | ±8℃ | ±6℃ | ±15℃ | ±3℃ |

| Heating Speed | Slow | Quick | Slow | Very quick |

| Working Environment | A little pollution after fired | Clean | Heavy pollution | Clean |

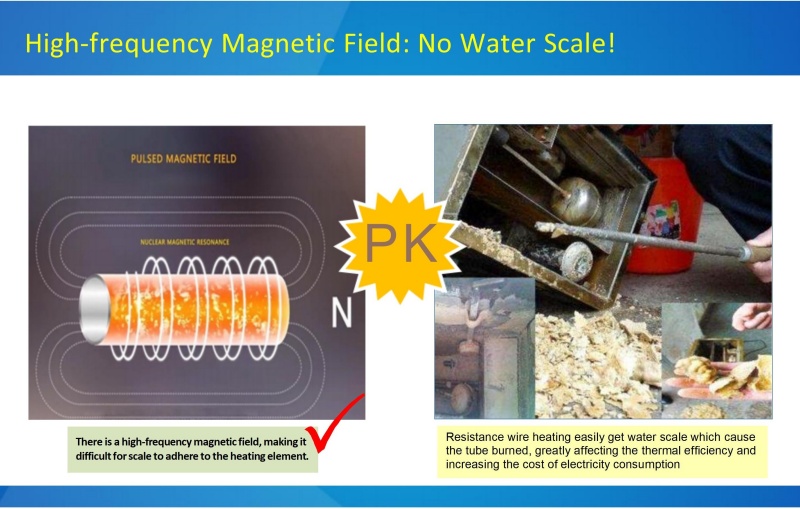

| Production Risk Index | Risk of gas leakage, complicated pipelines | Risk of electricity leakage pipe inner wall easy be scaling | Risk of high temperature, heavy pollution | No risk of leakage, water & electricity separated completely |

| Operational Performance | Complicated | Simple | Complicated | Simple |

Cost Analysis of Various Steam Boiler (Based on 1 Ton Steam Output)

| Item | Coal Fired Boiler | Diesel Fired Boiler | Gas Fired Boiler | Resistance Wire Heating Boiler | Induction Heating Boiler |

| Fuel Price | RMB2.00/KG | RMB8.00/L | RMB4.60/M3 | RMB0.50/KWH | RMB0.50KWH |

| Cost Per Hour | 200KG/H*2=RMB400 | 80L/H*8=RMB640 | 85M3*4.60=RMB391 | 720KW/H*0.5=RMB360 | 640KW/H*0.5=RMB320 |

| Annual Cost Per Year | 400*24*300=RMB2,880K | 640*24*300=RMB4,610K | 391*24*300=RMB2,820K | 360*24*300=RMB2,592K | 320*24*300=RMB2,304K |

| Pollution Cost | RMB30K/Year | RMB30K/Year | RMB15K/Year | 0 | 0 |

| Labor Cost | RMB5,000*2=RMB120K | RMB5,000*2=RMB120K | 0 | 0 | 0 |

| Installation & Inspection Fees | RMB30K/Year | RMB30K/Year | RMB30K/Year | 0 | 0 |

| maintenance cost | RMB5K/Year | RMB5K/Year | RMB5K/Year | RMB5K/Year | 0 |

| Total Annual Cost | RMB3,065K~USD437.9K | RMB4,795K~USD685K | RMB2,870K~USD410K | RMB2,597K~USD371K | RMB2,304K~USD329.1K |