The Working Principle of Electromagnetic Frequency Conversion Energy Storage Induction Heating Steam Generator

Electromagnetic induction heating steam generator, also known as electromagnetic steam boiler, is a power device that uses the principle of electromagnetic induction eddy current heating to convert electrical energy into thermal energy, and then convert thermal energy into steam. Compared to traditional resistance heating steam generators, electromagnetic steam generators are more economical, capable, safer, and longer lifespan.The structure of the electromagnetic steam generator mainly consists of an electromagnetic induction heater, a pressure vessel, and an induction heating coil, as well as water level display and pressure. In short, induction water boilers are an efficient and environmentally friendly heater that utilizes the principle of electromagnetic induction to convert electrical energy into thermal energy and achieve heating by heating water.

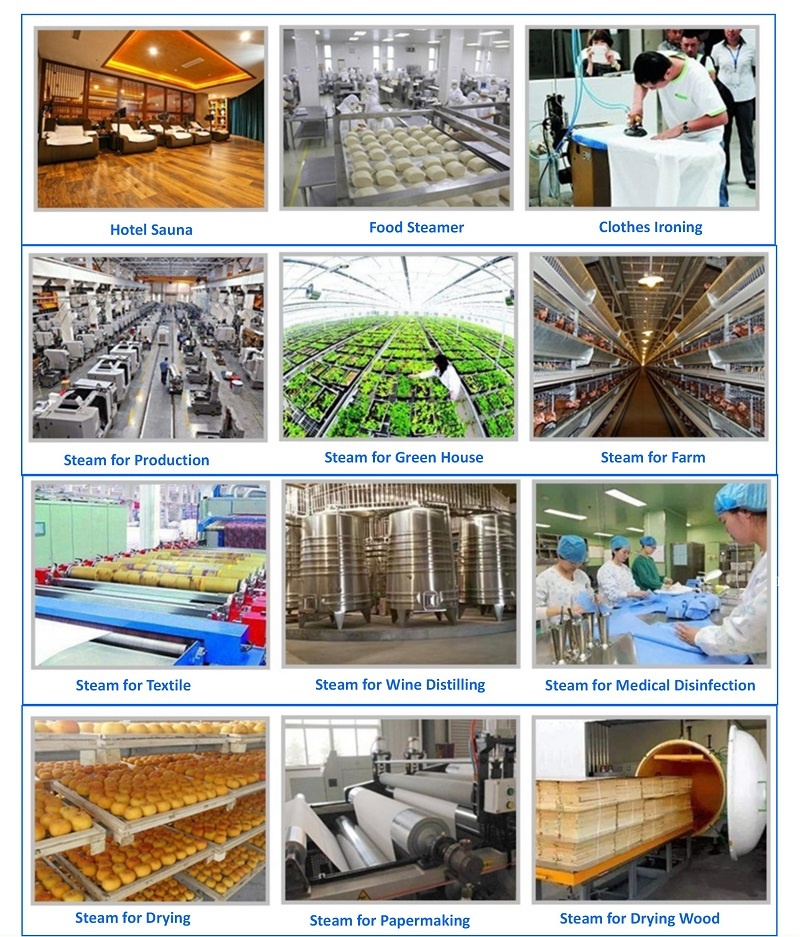

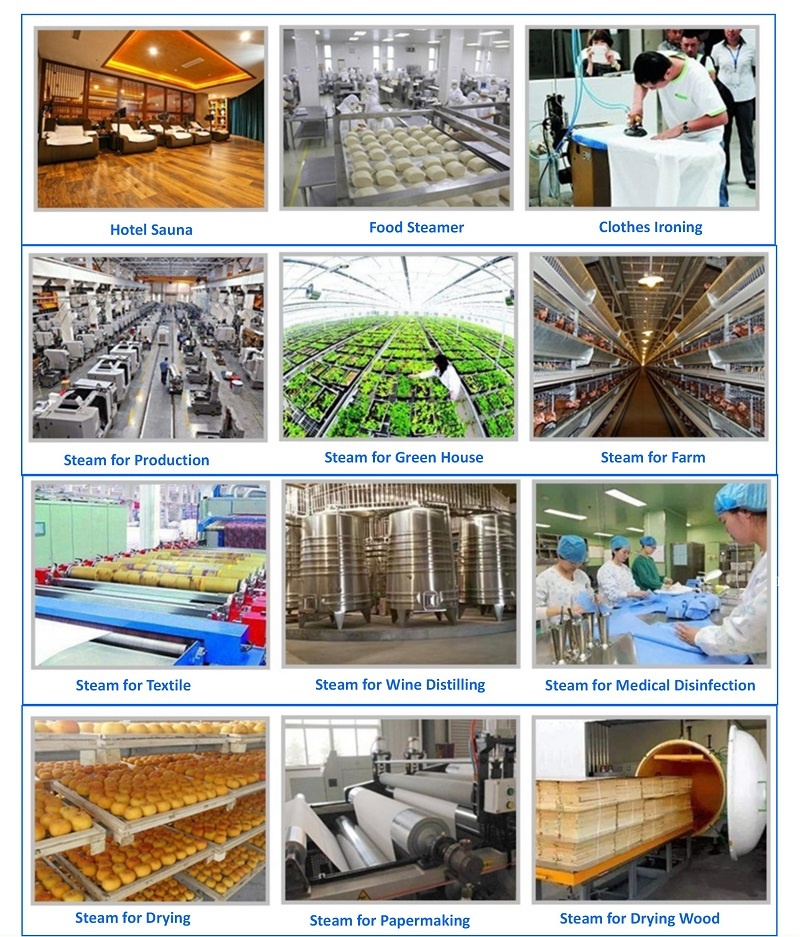

Applications for Electromagnetic Frequency Conversion Energy Storage Induction Heating Steam Generator:

1. Petroleum and chemical industry: polymerization, condensation, distillation, melting, dehydration, forced insulation.

2. Oil and Fat Industry: Temperature control and heating of reactors for processes such as fatty acid distillation, oil decomposition, concentration, esterification, and vacuum degumming.

3. Synthetic fiber industry: polymerization, melting, spinning, drawing, drying.

4. Textile Printing and Dyeing Operations: Heating of heat-setting rollers, heating in drying chambers, and thermal dyeing.

5. Nonwoven Industry: Nonwoven fabric.

6. Feed Industry: Drying.

7. Plastic and Rubber Industry: Hot pressing, calendering, extrusion, and vulcanization molding.

8. Paper industry: Drying and corrugated paper processing.

9. Timber Industry: Multi-layer boards, fiberboard press forming, laminated board heating, hot press plate heating, oil press machine temperature control, and wood drying.

10. Construction Materials Work: Gypsum board drying, asphalt heating, and concrete component curing.

11. Machinery Industry: Spray painting and printing drying.

Main Features of Electromagnetic Frequency Conversion Energy Storage Induction Heating Steam Generator:

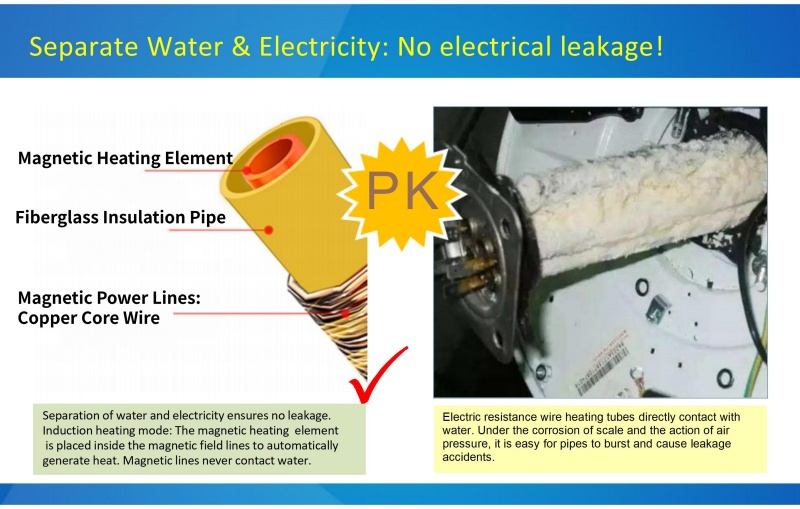

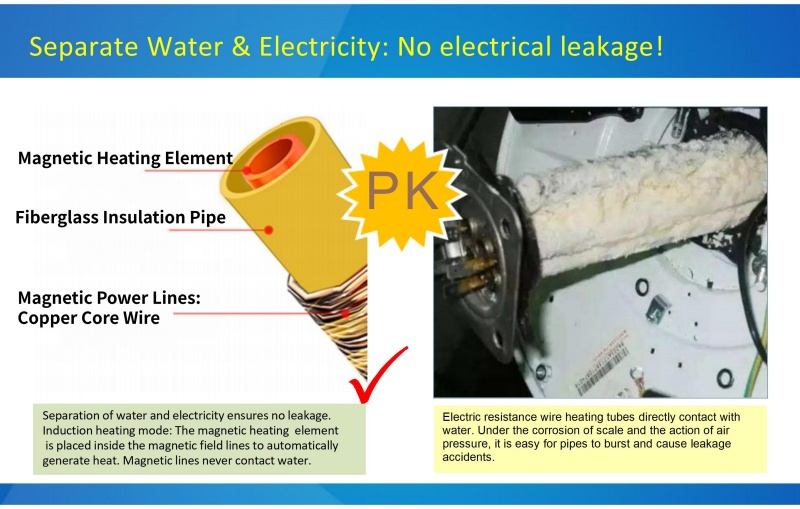

· 100% Safety: Electromagnetic Frequency Conversion Energy Storage Induction Heating Steam Generator truly achieves complete separation of water and electricity, eliminating the safety hazards of conventional electric boilers. The product maintains constant power output and features soft-start control, ensuring smooth operation without impact.

·30% Energy-saving Type: High-efficiency electromagnetic heating, rapid temperature rise, no scaling, maintenance-free. The steam generator can be set automatically with standard temperature, low operating costs, and requires no personnel supervision, it significantly reduces operating costs! With no thermal decay, it is more energy-efficient.

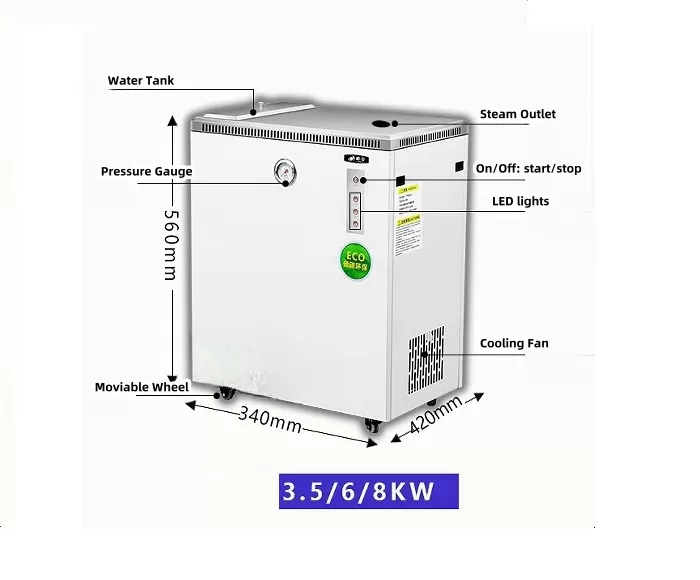

· Compact size: The electromagnetic steam generator has a small footprint, featuring an aesthetically designed exterior that allows for flexible installation and placement, minimizing space occupation as much as possible.

· Independent Drainage: This device features a dedicated drainage structure with a separate drainage port, ensuring simple and convenient operation for easy cleaning, drainage, and maintenance.

Technical Parameter:

6-15KW NEW DESIGN Electromagnetic Frequency Conversion Energy Storage Steam Generator

| Model No. | ZG-EH06-SGN | ZG-EH08-SGN | ZG-EH10-SGN | ZG-EH12-SGN | ZG-EH15-SGN |

| Rated Power | 6KW | 8KW | 10KW | 12KW | 16KW |

| Input Voltage | 220V-1P, 50/60Hz | 380V-3P, 50/60Hz | 380V-3P, 50/60Hz | 380V-3P, 50/60Hz | 380V-3P, 50/60Hz |

| Heating Current | 27.3A | 12.2A | 15.2A | 18.3A | 22.8A |

| Steam Temperature | 100-171℃ adjustable | 100-171℃ adjustable | 100-171℃ adjustable | 100-171℃ adjustable | 100-171℃ adjustable |

| Steam Pressure | 0.1~0.7Mpa adjustable | 0.1~0.7Mpa adjustable | 0.1~0.7Mpa adjustable | 0.1~0.7Mpa adjustable | 0.1~0.7Mpa adjustable |

| Steam Volume | 8KGs/H | 12KGs/H | 14KGs/H | 16KGs/H | 24KGs/H |

| Heat Exchange Rate | ≧98% | ≧98% | ≧98% | ≧98% | ≧98% |

| Steam Outlet Pipe | DN15 | DN15 | DN15 | DN15 | DN15 |

| Safety Value Pipe | DN15 | DN15 | DN15 | DN15 | DN15 |

| Water Inlet Pipe | DN4 | DN15 | DN15 | DN15 | DN15 |

| Sewage Pipe | DN15 | DN15 | DN15 | DN15 | DN15 |

| Dimension | 60*50*70CM3 | 74*55*80CM3 |

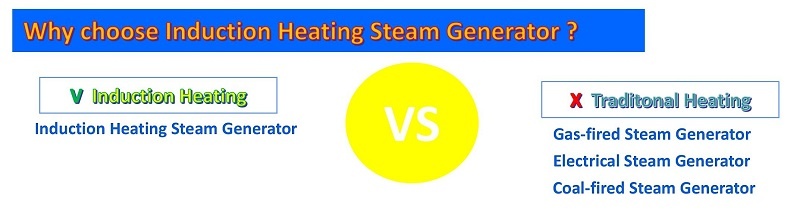

Why choose Electromagnetic Frequency Conversion Energy Storage Steam Generator?

Please check the table for comparison.

| Steam Generator Type | Gas-fired Type | Electrical Type | Coal-fired Type | Induction Heating Type |

| Energy Used | Gas by Fire | Resistance Wire by Electricity | Coal by Fire | Induction Heating by Electricity |

| Heat Exchange Rate | 85% | 88% | 75% | 98% |

| Need Someone on Duty | Yes | No | Yes | No |

| Temperature Control Accuracy | ±8℃ | ±6℃ | ±15℃ | ±3℃ |

| Heating Speed | Slow | Quick | Slow | Very quick |

| Working Environment | A little pollution after fired | Clean | Heavy pollution | Clean |

| Production Risk Index | Risk of gas leakage, complicated pipelines | Risk of electricity leakage pipe inner wall easy be scaling | Risk of high temperature, heavy pollution | No risk of leakage, water & electricity separated completely |

| Operational Performance | Complicated | Simple | Complicated | Simple |