Induction brazing, though known for its efficiency and precision, comes with several limitations that may affect its performance in specific applications. It requires clean, oxide-free surfaces to ensure proper joint formation, and oxidation during heating can lead to the loss of essential alloying elements. Materials such as aluminum, which develop highly stable oxide layers, present additional challenges. Moreover, maintaining accurate temperature control and uniform heat distribution is crucial, particularly when working with alloys that have narrow melting ranges. Recognizing these limitations is vital for choosing the right brazing technique and achieving consistent, high-quality results.

Key Points Explained

1. Lack of Refining Capacity

Induction brazing requires charge materials to be clean, oxide-free, and of a precisely known composition. Any impurities or oxide layers can interfere with wetting and bonding, reducing joint quality. Unlike processes such as welding or melting, induction brazing does not refine or purify the base materials during operation. This limitation becomes particularly critical when working with metals that are easily oxidized or contaminated, as the process cannot correct these material deficiencies.

2. Oxidation and Loss of Alloying Elements

Oxidation during induction brazing can cause the loss of essential alloying elements, altering the intended chemical composition of the joint. To maintain the desired properties, these lost elements often need to be replenished. Failure to do so may result in inconsistent mechanical strength or corrosion resistance. Consequently, strict control of the brazing atmosphere and precise temperature management are necessary to minimize oxidation and ensure uniform, high-quality results.

3. Challenges with Aluminum and Other Oxidizable Materials

Aluminum and similar metals pose significant challenges in induction brazing due to their strong tendency to oxidize. Aluminum forms a stable and adherent oxide layer (Al₂O₃) that prevents the filler metal from properly wetting the surface, resulting in poor joint formation. This oxide layer must be effectively disrupted or removed prior to brazing and prevented from reforming until the filler metal has completely solidified. Managing this process adds complexity, often requiring the use of specialized fluxes, controlled atmospheres, or surface treatments to achieve reliable bonding.

4. Precise Temperature Control and Homogeneous Thermal Distribution

Successful induction brazing depends heavily on accurate temperature regulation and uniform heat distribution. When the melting points of the base and filler metals are close, even slight temperature deviations can cause incomplete wetting, premature melting of the base material, or weak joints. Achieving homogeneous thermal distribution across the joint area is equally important to ensure consistent metallurgical bonding. Uneven heating may lead to localized overheating, incomplete filler flow, or thermal stresses that compromise the overall strength and durability of the brazed assembly.

5. Material Compatibility

Not all materials are well-suited for induction brazing. Metals that are highly reactive, have complex alloy compositions, or form stable oxide layers may present difficulties in achieving proper wetting and bonding. Selecting compatible base and filler metals is therefore essential to ensure strong, durable joints without unwanted reactions such as intermetallic formation or embrittlement. Careful evaluation of metallurgical compatibility helps prevent joint failure and ensures consistent performance in service.

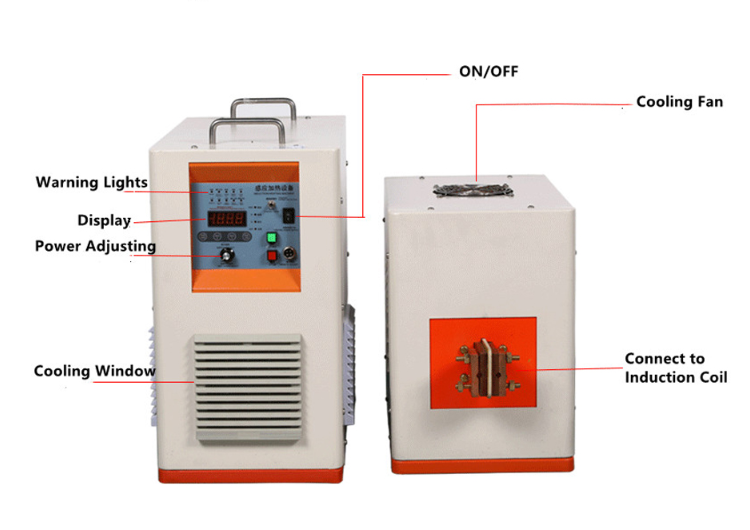

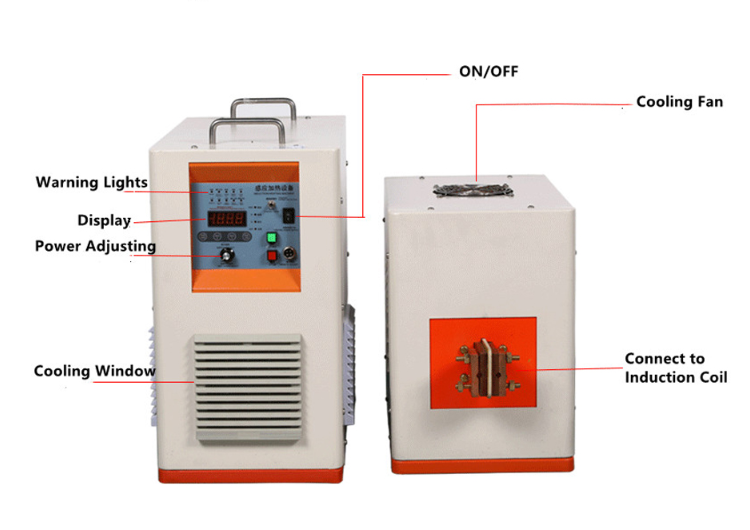

6. Equipment and Process Complexity

Induction brazing systems are often more sophisticated and costly than other brazing setups, requiring specialized equipment and precise control systems. Skilled operators are needed to manage process parameters such as frequency, power input, heating time, and coil positioning. The method’s complexity demands a thorough understanding of both the materials involved and the equipment’s operational characteristics. While this complexity allows for high precision, it also increases setup time, operational costs, and the need for technical expertise.

Summary

Induction brazing offers significant advantages, such as rapid heating, precise temperature control, and the ability to produce consistent, high-quality joints. However, it also presents several limitations that must be carefully addressed. These include the need for clean, oxide-free materials, the risk of alloying element loss due to oxidation, challenges associated with highly oxidizable metals like aluminum, and the necessity for precise temperature control and uniform thermal distribution. Additionally, considerations such as material compatibility and the complexity of equipment and process management further influence the success of induction brazing. A thorough understanding of these factors is essential for selecting the most appropriate brazing method and achieving reliable, durable results.

Summary Table:

| Limitation | Key Challenges |

|---|

| Lack of Refining Capacity | Requires clean, oxide-free materials; no refining during brazing. |

| Oxidation and Loss of Alloying Elements | Alloying elements may oxidize, requiring re-addition and careful monitoring. |

| Challenges with Aluminum | Aluminum oxide layer must be suppressed and managed for successful brazing. |

| Precise Temperature Control | Critical for materials with closely matched melting ranges. |

| Material Compatibility | Not all materials are suitable; base and filler metals must be compatible. |

| Equipment and Process Complexity | Requires skilled operators and complex, expensive equipment. |