Application Ranges of Coupling Medium Frequency Induction Heating Machine for Fitting and Removing

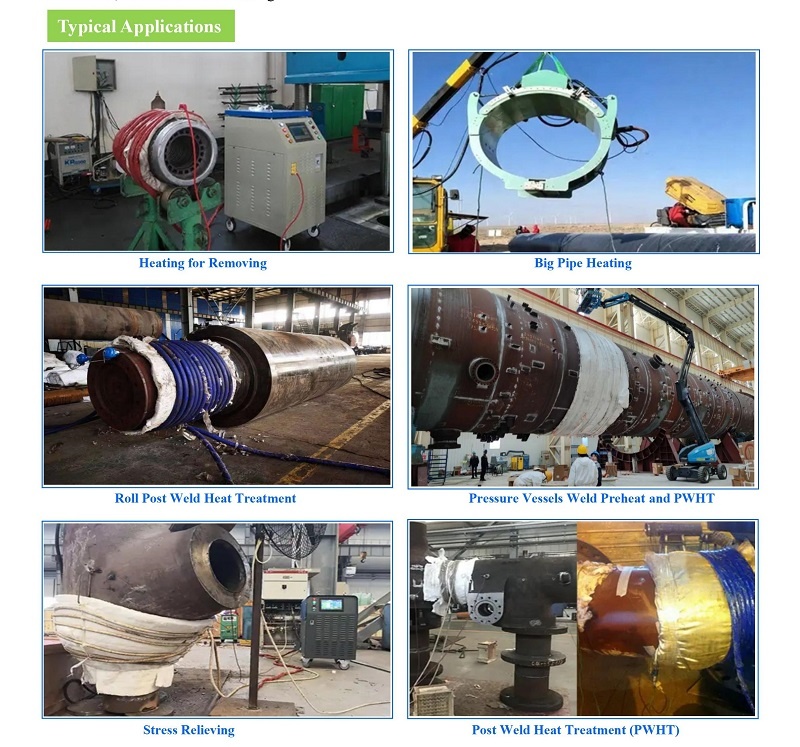

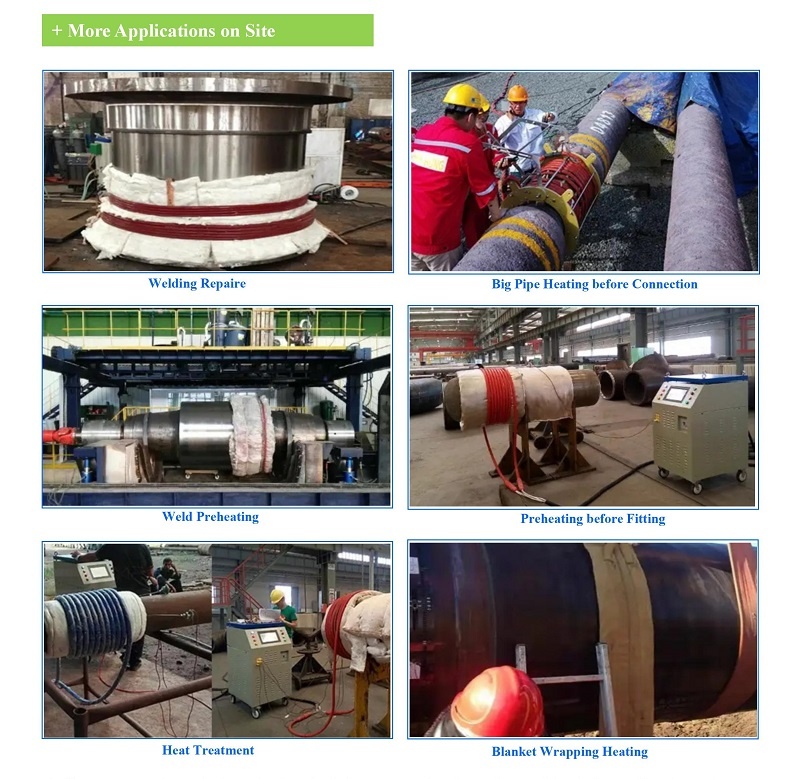

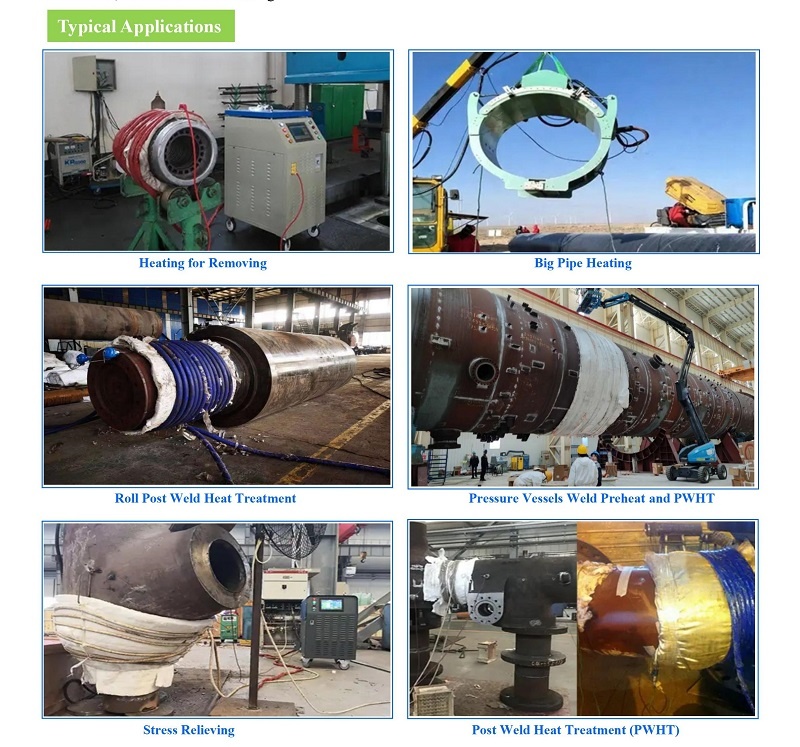

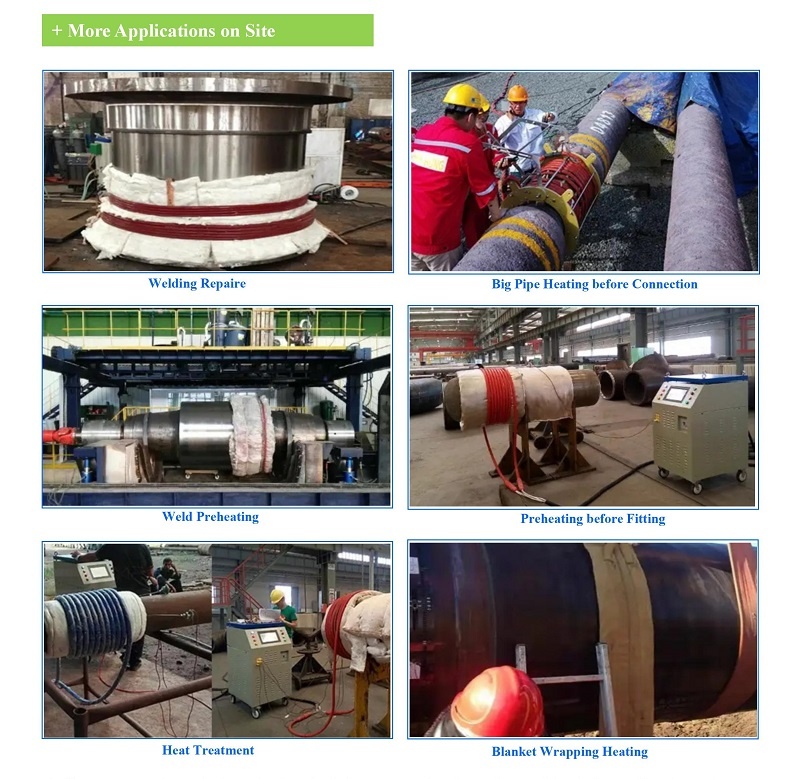

1. Removing and Thermal Assembly & Disassembly-Gear, Motor, Roll, Coupling

2. Shaft Manufacturing and Repair- Hot Forging, Bending, Fitting

3. Weld Joint Preheat and PWHT - Pipelines, Pressure Vessels, Heavy Steel Structures, Shipbuilding, Onshore & Offshore Platforms & Mining machinery

4. Pipeline Fabrication & Coating & Unfreezing

5. Boiler, Tank and Fluid Heating

Main Features of Coupling Medium Frequency Induction Heating Machine for Fitting and Removing

1, Save electricity at least 30% and highest to 80%, especially for big power machine;

2, No influence on working environment;

3, High efficiency: induction heating system has heat energy utilization rate of 95%+;

4, Heating fast, accurate temperature control;

5, Can work for a long time in harsh environments;

6, Low cost of power consumption compare to traditional resistance wire heating;

7, No unsafe factors compare to traditional heating: surface temperature only about 50℃~80℃;

8, External control like PLC can be connected.

Technical Parameter of Coupling Medium Frequency Induction Heating Machine for Fitting and Removing

| Model No. | Input Power | Rated Power | Input Current | Output Frequency | Coil Copper Area | Coil Length | Inductance | Heat Exchange |

| ZG-MF10-E | 380V/3P | 10KW | 15A | 5-30KHZ | 10-16mm2 | 33-36M | 180-220μH | ≧98% |

| ZG-MF15-E | 380V/3P | 15KW | 22.5A | 5-30KHZ | 10-16mm2 | 30-33M | 160-180μH | ≧98% |

| ZG-MF20-E | 380V/3P | 20KW | 30A | 5-30KHZ | 16-25mm2 | 26-32M | 140-160μH | ≧98% |

| ZG-MF25-E | 380V/3P | 25KW | 37.5A | 5-30KHZ | 16-25mm2 | 26-30M | 90-110μH | ≧98% |

| ZG-MF30-E | 380V/3P | 30KW | 45A | 5-30KHZ | 25-30mm2 | 26-30M | 90-130μH | ≧98% |

| ZG-MF40-E | 380V/3P | 40KW | 60A | 5-30KHZ | 25-35mm2 | 38-42M | 230-280μH | ≧98% |

| ZG-MF50-E | 380V/3P | 50KW | 75A | 5-30KHZ | 25-35mm2 | 38-40M | 120-220μH | ≧98% |

| ZG-MF60-E | 380V/3P | 60KW | 90A | 5-30KHZ | 25-40mm2 | 36-40M | 150-180μH | ≧98% |

| ZG-MF80-E | 380V/3P | 80KW | 120A | 5-30KHZ | 40-50mm2 | 36-40M | 130-160μH | ≧98% |

| ZG-MF100-E | 380V/3P | 100KW | 150A | 5-30KHZ | 50-70mm2 | 26-30M | 130-160μH | ≧98% |

| ZG-MF120-E | 380V/3P | 120KW | 180A | 5-30KHZ | 70mm2 | 26-30M | 130μH | ≧98% |

| ZG-MF160-E | 380V/3P | 160KW | 240A | 5-30KHZ | 2*50mm2 | 36-40M | 120μH | ≧98% |

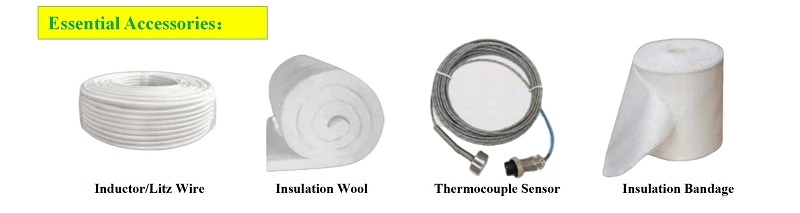

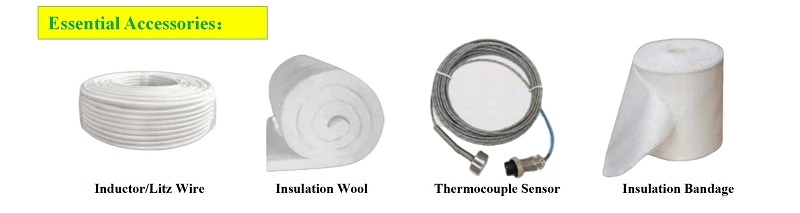

Induction Coils can be made different shapes as requests

Straight and Fillet Blanket Coil is easily for moving to heat partly and wrapping on the workpieces.

Clamp coil can be attached to the workpieces anywhere need to heat.

Fixed Circle Coil is proper for those standard diameter of pipes rods shafts etc.

C Type Coil will be more convenient for Rapid Preheating.

Soft Cable Coil fits for long time PWHT like Stress Relief and Hydrogen Elimination.

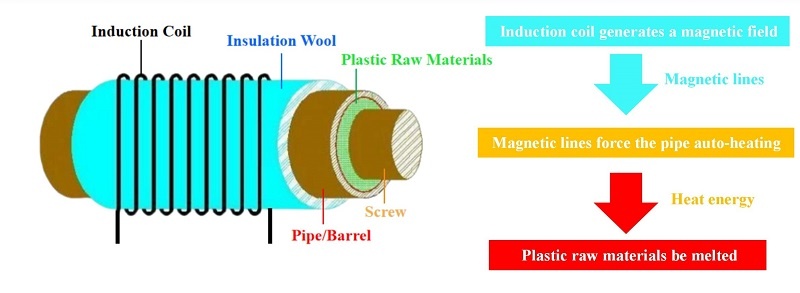

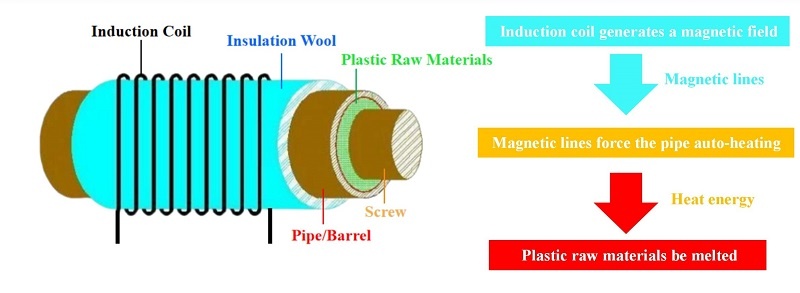

Multi-function microcomputer Medium frequency induction heater adopts the principle of electromagnetic induction to convert electrical energy into thermal energy. The electromagnetic heating controller rectifies 220V, 50/60HZ AC power into DC power, which is then converted into high-frequency high voltage power with a frequency of 20-40KHZ, or 380V 50/60HZ three-phase AC power into DC power, which is then converted into high-frequency low voltage high current power with a frequency of 10-30KHz, for industrial product heating. Electromagnetic heating coil: High frequency and high voltage currents flowing through the coil generate a rapidly changing alternating magnetic field. When an iron or steel containing container is placed on top of it, the surface of the container cuts the alternating magnetic field lines and generates alternating currents (i.e. eddy currents) in the metal part at the bottom of the container. The eddy currents cause the carriers at the bottom of the container to move irregularly at high speed, collide and rub against each other, and generate thermal energy. Thus achieving the effect of heating the item. It is a heating method that converts electrical energy into magnetic energy to induce eddy currents on the surface of the heated steel body. This method fundamentally solves the problem of low thermal efficiency caused by resistance heating such as electric heating plates and coils, which are heated through thermal conduction.