The Structure & Working Principle of Bearing Heater :

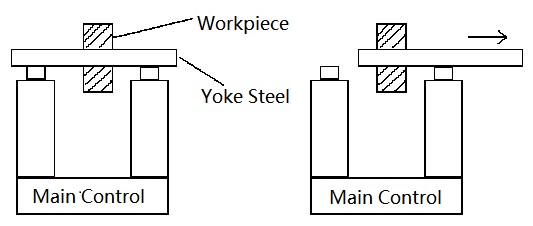

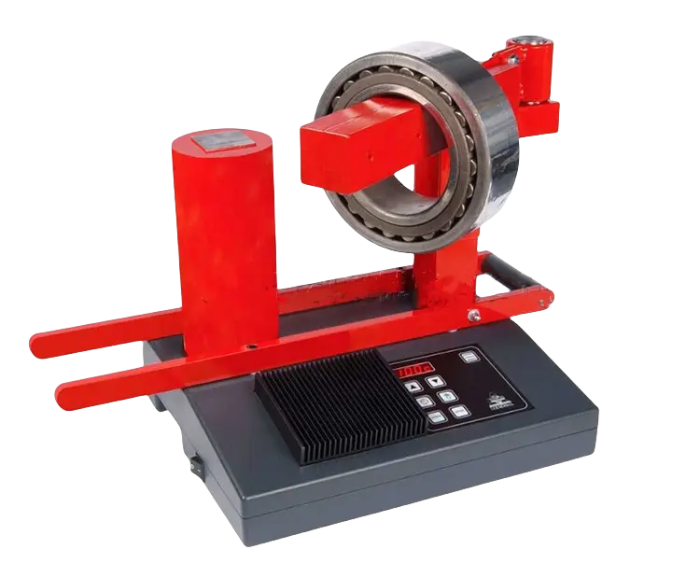

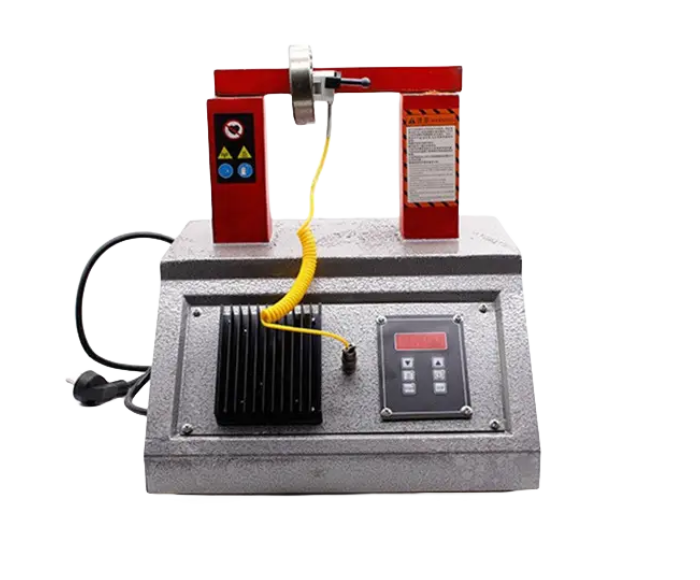

The bearing induction heater is a kind of air-cooling frequency induction heating device, which is composed of induction heating main control, yoke steel, temperature controller & sensor and other accessories. The purpose of heating the bearing is to cause the bearing to produce thermal expansion, so that the bearing can be smoothly sleeved on the shaft.

In fact, the working principle of bearing heater is applied electromagnetic induction heating, which is actually the use of magnetic fields. When we put the bearing on the yoke steel, the circuit is closed and a magnetic field is formed. The heated work piece is a equivalent to a resistance. The current in the magnetic field will accumulate every time it passes through the resistance. As a result, the workpiece is also heated.