Over time, induction heating has increasingly supplanted traditional heating systems across various industries. Its appeal lies in its ability to deliver pollution-free, localized, consistent, and precise heating.

Yet, many are unaware of how induction coil design impacts heating efficiency.

This article delves into the fundamentals of induction heating coil design, exploring the various types of induction coils available. But first, let's understand how an induction heating coil operates.

How Does an Induction Heating Coil Work?

The coil stands as the primary component of induction heating equipment, with its design and quality crucial in determining the effectiveness of heating a workpiece.

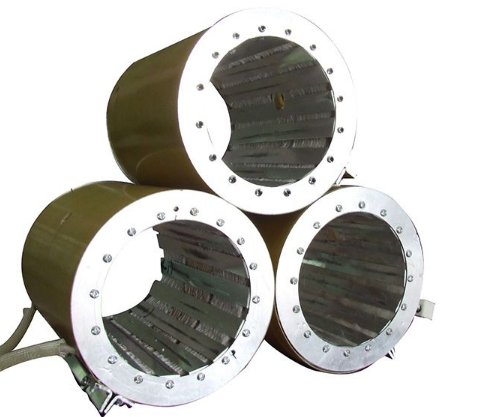

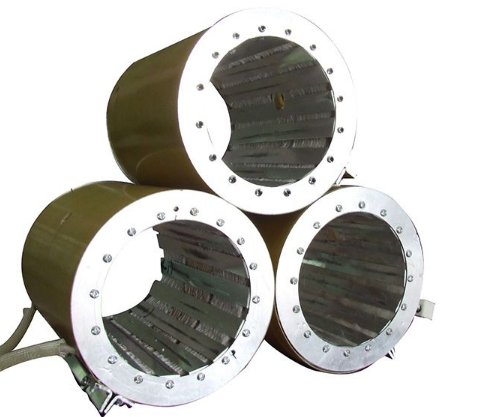

An induction coil typically consists of copper tubing shaped into a coil configuration. Depending on the number of turns in the copper tube, the coil is termed either helical or solenoid-wound.

When electrical power flows through the coil, it generates an electromagnetic field, driven by the flow of alternating current (AC).

This alternating electromagnetic field induces a current within the workpiece, resulting in heat generation due to squared resistance losses.

The intensity of the induced current in the workpiece is contingent upon the electromagnetic field intensity of the coil. This energy transfer phenomenon is known as the Eddy Current Effect or the Transformer Effect.

Types of Induction Coils

Induction heating employs a variety of coils with distinct heating behaviors and applications. Let's explore some common types of induction coils:

Single-Turn Coil

Also known as a solid inductor, the single-turn coil heats the workpiece along a narrow band and can scan the length of the workpiece.

Internal Coil

This coil is uniquely designed to heat the inner surfaces of holes, reducing the distance from the holes' surfaces to optimize heat distribution.

Multi-Turn Helical Coil

Featuring several turns, this coil creates a longer heating pattern.

Multi-Position Helical Coil

Ideal for comprehensive heating processes, this coil can be configured into multiple positions, typically accommodating up to eight positions.

Curved Channel Coil

Utilized on rotary tables, these coils facilitate a step in the multistep assembly process.

Pancake Coil

Used to heat a workpiece from one side only, particularly suitable for flat-surfaced metals. It heats a small, narrow band from the center.

Hairpin Coil

Available as single or multiple-turn coils, hairpin coils are employed to heat long and thin parts, as well as moving steel or aluminum.

Now that we've explored various coil types, let's delve into the basics of induction heating coil design.

Considerations for Induction Heating Coil Design

The design of an induction heating coil significantly impacts the efficiency of the induction heating process. Therefore, careful selection of its components is essential.

Tubing Selection

Opt for high-conductivity copper tubing for the coil, ensuring efficient water cooling. A copper tube with an outer diameter of at least 0.32 cm facilitates easy cooling. For applications requiring high power, the diameter can extend up to 5.1 cm.

Coil Turn Numbers

Multi-turn coils are suitable for single-shot heating of large-diameter workpieces. These coils feature multiple turns, increasing the overall coil proportion. However, achieving uniform heating becomes challenging when the coil diameter exceeds 4x–8x.

Single-Turn Coils

Single-turn coils are ideal for heating narrow-diameter bands. The dimensions of single-turn coils vary slightly based on size.

Design of Coil Leads

The design and structure of the work-coil lead significantly influence coil performance. The coil forms a tank circuit, and all leads connecting the tank capacitor to the coil contribute to inductance. Higher inductance in the coil heating area counterbalances the effect of lead inductance.

Coil Bracing

Proper coil bracing is crucial in induction coil design to prevent unwanted movement caused by magnetomotive forces. During induction heating, electric current flow in the coil and workpiece generates these forces, which can become uncontrollable without adequate bracing.

Distance of Coupling

Coupling is the term used for the gap between the induction coil and the workpiece.

For progressive heating, the coupling distance should be 0.19 cm.

However, if the workpiece is a magnetic material, the coupling distance should range from 0.25 to 0.38 inches.

The small gap between the coil and the workpiece is known as tight coupling, while the large gap is called loose coupling.

Induction Coil Installation

Proper installation of the induction coil is as critical as its design. Incorrect installation can lead to significant downtime. It's advisable to follow the manufacturer’s manual for coil installation or replacement.

When replacing the coil on an induction heating device, keep the following points in mind:

1. Ensure the main switch and cooling water are turned off.

2. Place a container beneath the inductor to catch any leaking cooling water.

3. Loosen the nuts on the connector jaws to release the thrust parts carefully.

4. Remove the old coil and install the new one.

5. Ensure a tight fit between the coil and the coaxial transformers.

Note: Always use brass nuts and washers.

The induction heating coil is a vital component of the induction heating machine, requiring careful consideration in its design.

This comprehensive guide covers various aspects of induction heating coils, including design, functioning, types, and more, providing you with sufficient knowledge on the subject.